BAER Assembly tools for repairing defective threads

A stripped thread, rust or normal wear and tear from frequent use - there are many ways a thread can become damaged. Instead of thinking about replacing the entire component, take a look at our simple solutions for thread repair. After all, why make something new when you can fix it? With our high-quality assembly tools, you can save time and money in this way without sacrificing load-bearing capacity, because the repaired thread has a higher load-bearing capacity than the original thread.

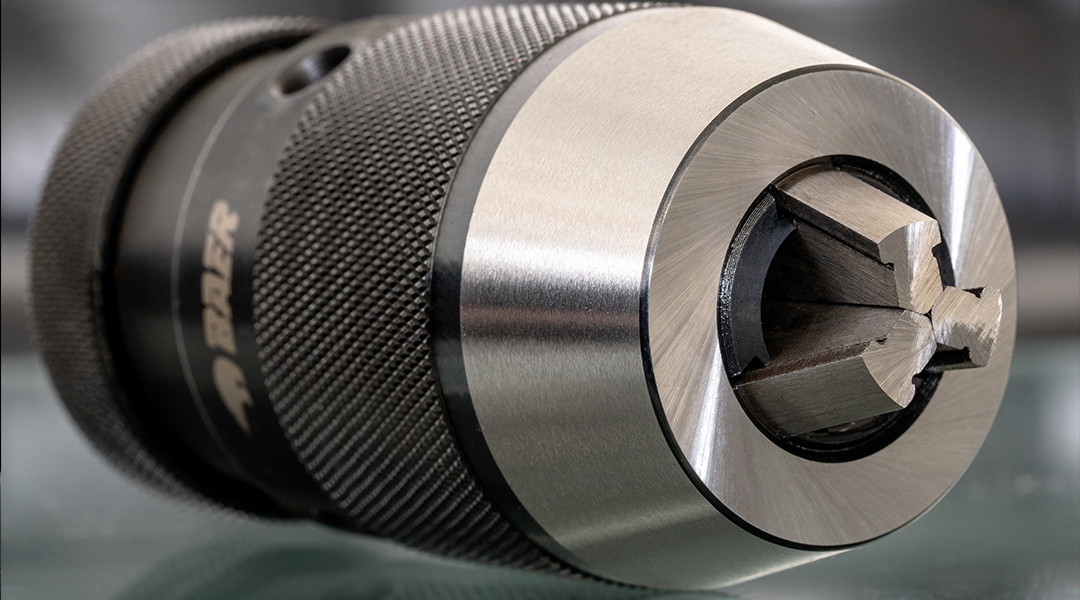

We at BAER are experts when it comes to drilling and repairing threads. In our Online-Shop you will find everything you need to repair or strengthen your damaged threads, from the appropriate inserts to thread insertion tools. All assembly tools are manufactured with the highest precision and create the best conditions for a good success of your project. In our family business, we have been involved in the development and manufacture of the highest quality threading tools for 40 years. You can rely on our experience!

Thread repair with assembly tool - How does it actually work?

Basically, a special insert is inserted into the existing, damaged thread during repair with assembly tools. The original nominal diameter is retained, so the renewed thread can continue to be used without further adjustments. Another advantage of this process is that the thread is not only repaired, but also strengthened at the same time. This is therefore also referred to as thread armoring. You therefore do not have to expect any loss of service life or load capacity.

In addition to the appropriate inserts, you will need various assembly tools to carry out this repair. For a high-quality result, it is best to use only thread insert tools that are designed for exactly this task. In our assortment you will find two product lines that provide all the parts you need. With us, you get all assembly tools from a single source. This way, you can always rely on consistent quality and precision and the thread repair will succeed in no time.

BaerCoil® - Our product line for thread repair with wire thread inserts

Our BaerCoil® product line makes it easy to repair a defective thread using a wire thread insert. Here we have compiled all the installation tools you need to carry it out. We carry installation tools for manual repair as well as machine installation tools. To prepare the core hole, you will find taper countersinks and core hole drills at Online-Shop.

Also helpful are tang breakers, a special installation tool with which you can break the tang on the thread insert. However, you do not need this for a spark plug thread or for larger dimensions where the tang can be broken with needle-nose pliers. Of course, you will also find the appropriate thread inserts for all common international standards in our range. And with the unscrewing tools, you will also succeed in dismantling thread inserts effortlessly. This completes the full range of assembly tools.

Each of our BaerCoil® thread insert tools can be ordered as a single piece. So you only need to purchase the assembly tool you don't already have in yours. In addition, we also offer carefully assembled sets with our thread repair kits and thread repair assortments . We recommend these especially if you have little experience with thread repair. This way you can be sure that no part is missing that you need for the thread repair. Please also note our automotive set, which we offer especially for the repair of spark plug threads.

How thread repair with BaerCoil® works

We want you to always be 100% satisfied with your result. That's why we not only support you with our wide range of products, we also have an open ear for your concerns at all times. You are not sure which assembly tool is the right one for you? You would like to have more information on how to perform a flawless thread repair? Are you working on a very special project and looking for special solutions? We can also make assembly tools specifically to your application or needs. Whatever is on your mind, we will take care of it. Use our contact form and we will calmly discuss an individual solution for your problem!

Our customer service will be happy to support you!

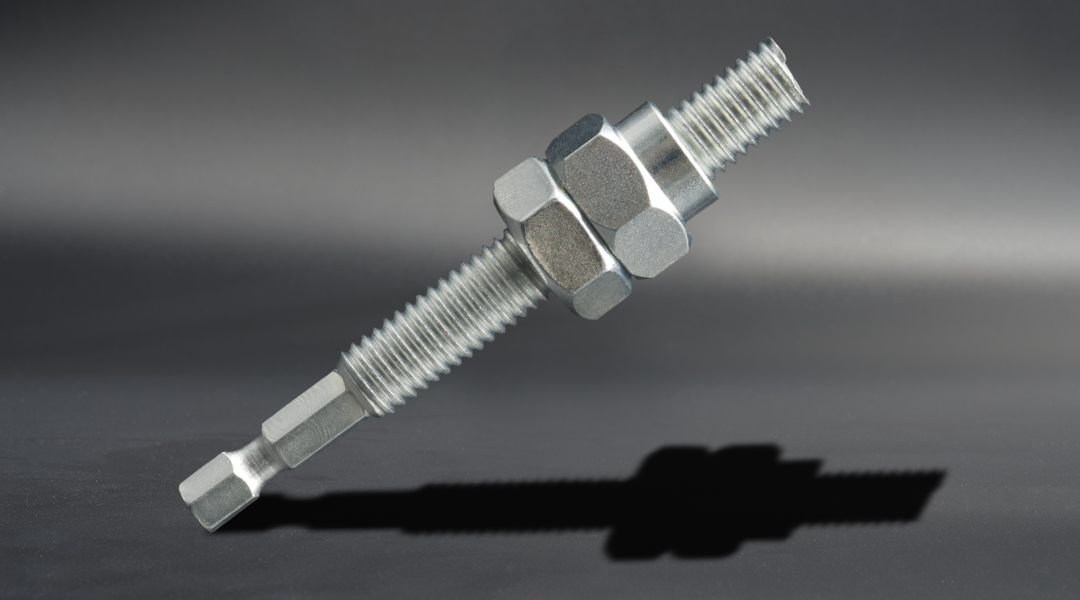

Even when using self-tapping thread inserts, the first step is to drill out the old thread. Then you can countersink the hole with a taper countersink. The thread is cut by the insert itself, so you don't have to pre-cut it. Instead, you simply place the thread insert on the installation tool and lock it with a nut. Then slowly screw it into the core hole. The installation tool has a bit holder, so you can easily use it with a cordless screwdriver, for example.

If you are working with a machine, please use our machine installation tools. To complete the process, simply loosen the lock nut again and unscrew the installation tool. Finished is the repaired thread and then even higher loadable than the original thread. The big advantage of this system is that you only need one special installation tool to screw in the thread insert, instead of many installation tools.

How thread repair works with BaerFix® assembly tool

Our BaerFix® system is particularly suitable for repairing and reinforcing heavily loaded threads. These thread ins erts are resistant to vibration and corrosion. They are self-tapping inserts, so you save some of the work steps and also assembly tools that are normally required for tapping.

In our Online-Shop you will find thread inserts for all areas of application. We also have the necessary assembly tools ready for you here. You will find core drills and taper countersinks for preparing the core hole as well as the necessary installation tools for the thread insert. Again, it depends on whether you install your thread insert by hand or with machine support. For both cases, you will find the required thread insert tools with us.

You also have the choice with our BaerFix® series: Do you want to purchase each installation tool individually or in a set or assortment tailored to your application? The decision is yours!

BaerFix® - Repair your threads with our self-tapping thread inserts

During the development of our system, in addition to high quality, user-friendliness and ergonomics of the assembly tools were at the top of the priority list. The application runs as follows and the respective assembly tools are used in the steps:

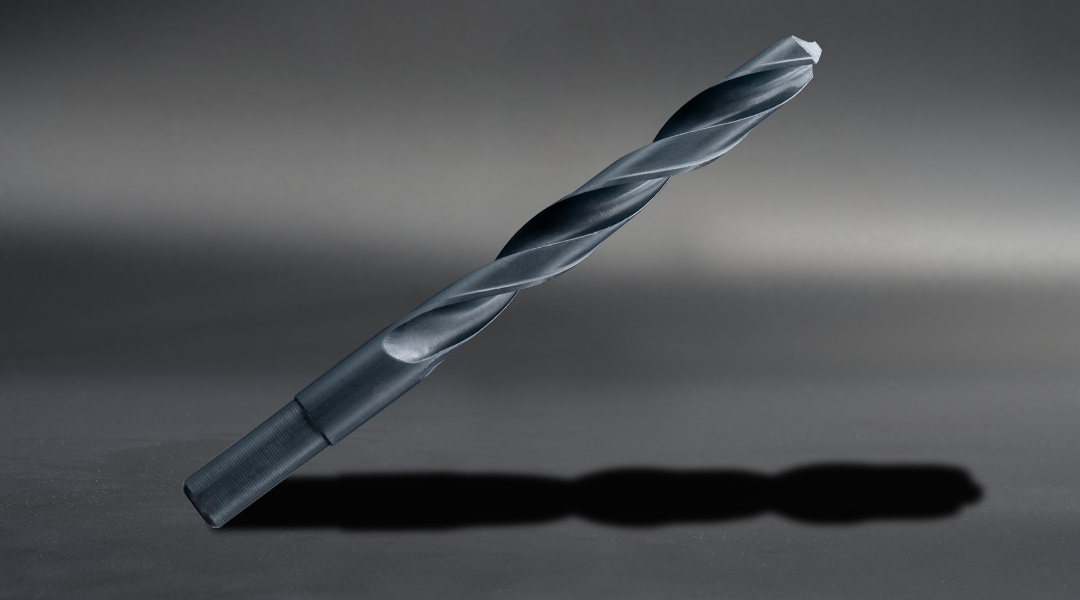

First, a twist drill is used, with which you drill out the damaged thread. You can then countersink this with a taper countersink. Next, you cut the thread with our tap , preferably using cutting paste. Now our special installation tools come into play. Select the appropriate installation tool, depending on whether you are working by hand or with a machine. You can now use this to screw in the thread insert. Now you only have to loosen the tang from the thread. The easiest way to do this is with our tang breaker. Your thread repair is already a success!

Your tools and BaerCoil® thread inserts - the perfect match.

Our thread inserts are standardized - usually according to DIN 8140 or similar - and therefore mostly suitable and compatible with wire thread inserts, installation tools and taps of other manufacturers. In addition, we can supply thread inserts according to the standards DIN 65536, EN 2944, LN 9039, LN 9499, NASM 21209 and others. Here we recommend to check these specifications carefully in case of need.