BAER Image film - for the love of tools

Quality and accuracy - that's what we live for

There is nothing that gives us more pleasure than seeing you - our customer - satisfied.

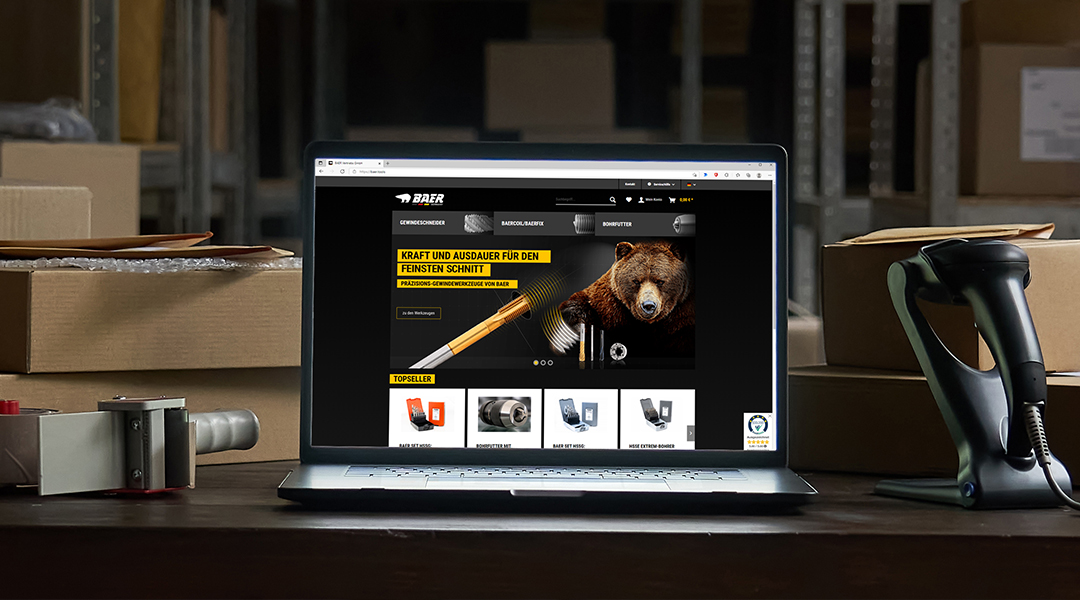

This begins with the first contact and continues in the further support. In between, there are several process steps that meet the highest standards of product quality and service. For example, we conduct a detailed consultation with you and offer you a convenient purchasing process at Online-Shop to find the right tools for you.

In this process, we purchase only the highest quality raw materials and select the best-fit supplier. The manufacturing process is meticulously prepared. As a result, we then offer threading tools and thread inserts that are extremely precise and give the customer excellent results in their production. The final inspection of the goods is the final touch to ensure that you have our high quality products in your hands.

Precision and quality are our top priorities when developing new innovations. In this way, we want to make it even easier for you to work with our products so that you can achieve excellent results more quickly. BAER-For us, quality means everything that benefits you - simply the best customer benefit! We regularly have ourselves audited by the independent TÜV Hessen in order to live up to this claim. We have already been awarded the ISO 9001:2015 quality management certificate several times - proof of our outstanding quality.

Strong focus on development and innovation - guarantee for best results

We get to know our customers' needs in detail so that we can incorporate them into the improvement of BAER products. Our team of experts systematically records and thoroughly analyzes all requests. Through close cooperation with other industry partners, hardening shops, coaters and research centers, we always keep our finger on the pulse. As a partner of the Baden-Württemberg Cooperative State University (DHBW), our commitment also makes an important contribution to the implementation of innovative idea proposals.

BAER Tools offer fast, efficient solutions for almost all craft and industrial tasks. Our extensive range of state-of-the-art powder metallurgical steel tools, the UniTap and thread repair are easy to use and delight our customers time and time again. That is our motivation.

Experience and tradition - a basic understanding of partnerships

We have been passionate about what we do for over 40 years and have focused on what we have learned the most: thread technology. The BAER Tools GmbH is a family business in the second generation and has great experience values. We identify ourselves completely with our products, solutions as well as the greatest possible service for our clientele. We always think in the long term - from the projects we implement to sustainable business improvement as a whole. As our customer, you can rely on us to be reliable at all times and to offer you innovative solutions for the future - true to our high quality standards!

BAER Product groups

Are you looking for taps, wire thread inserts or self-tapping thread inserts? We focus specifically on the development and production of such tools.

BAER Direct sales - taps and dies directly online from experts for experts

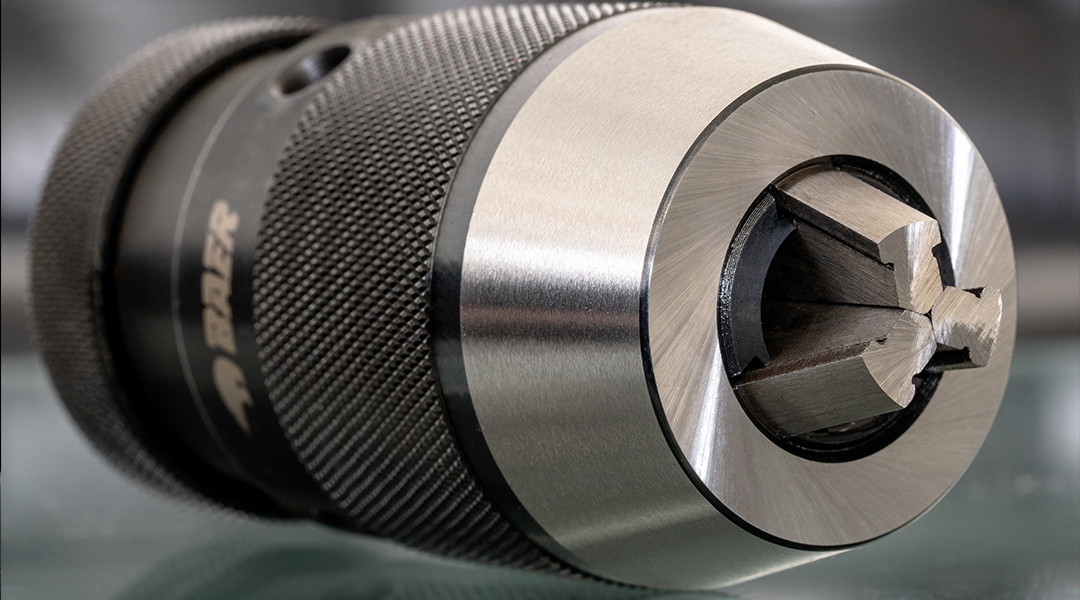

In the huge assortment you will find hand taps, combination taps, bit taps, machine taps, machine taps, taps, dies, hexagonal cutting nuts, twist drills, thread ring gauges, thread plug gauges, dies, die holders, self-tapping threaded bushes, wire thread inserts and drill chucks. You will receive these in all types and for the most diverse materials and applications, always in the best quality and at an excellent price/performance ratio. The tools speak for themselves.